How do polycarboxylate superplasticizer and silica fume interact in concrete materials?

How do polycarboxylate superplasticizer and silica fume interact in concrete materials?

Keywords

polycarboxylate powder, superplasticizers, silica fume, China polycarboxylate powder supplier

In the application process of modern concrete materials, silica fume has become an indispensable material.

Silica fume has a high amorphous silica content, extremely high specific surface area and dispersion, and the particles are round and dense. Compared with other active admixtures, it has the advantages of fast reaction and high activity. Adding 1 part of silica fume can replace about 4 times the amount of cement. As the amount of silica fume increases, the strength of concrete will also increase.

After adding silica fume to concrete, due to the large specific surface area of silica fume, a large amount of capillary water inside the concrete is restrained by microsilica fume, which reduces the bleeding inside the concrete and improves the bonding between cement slurry, aggregate and steel bars. And because the volcanic ash reaction of silica fume changes the pore structure inside the concrete, the large pores are reduced, the small pores are increased, and the pore diameter becomes thinner, which greatly improves the strength of the concrete.

Although silica fume has the above advantages, after adding microsilica fume to concrete, due to the microfiller effect, its own water absorption rate is large, the bleeding volume of fresh concrete is greatly reduced, the water demand is increased, the fluidity is insufficient, and other deficiencies, and silica fume The early hydration reaction of concrete is accelerated, which can easily lead to shrinkage and cracking of concrete.

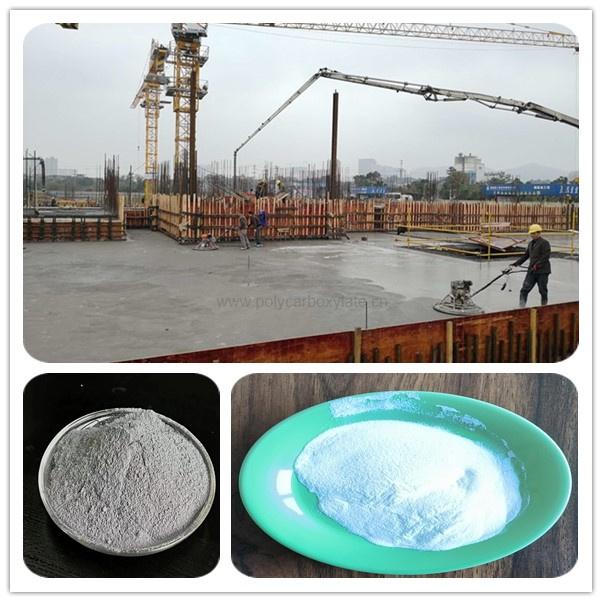

When microsilica fume is mixed into concrete, polycarboxylate superplasticizer must be added at the same time to ensure the necessary fluidity of concrete and the reinforcing effect of silica fume on concrete. In order to ensure the strength and fluidity of microsilica fume concrete, polycarboxylate high-efficiency water-reducing agent must be added when microsilica fume is added to the concrete.

Polycarboxylate water-reducing agent molecules form a hydration film on the surface of cement particles, which can significantly reduce the interfacial tension between water and cement particles, making it easier for cement particles to slide and disperse relative to each other, making agglomeration less likely to occur, thereby improving the fluidity of cement concrete.

Polycarboxylic acid high-efficiency water-reducing agent can greatly reduce the water demand of microsilica fume concrete and enhance the fluidity of concrete. Microsilica fume has the beneficial effect of polycarboxylic acid high-efficiency water-reducing agent - lubrication and dispersion of concrete materials, making both Interact, complement each other, and complement each other.